Contact or call

Weekday 9am-18pm- HK

- +852-2781-4113

- GZ

- +86-20-3887-8299

- SH

- +86-21-6427-0569

close

Contact or call

Weekday 9am-18pmclose

South China・ Manufacture・ 230 staff

South China・ Manufacture・ 230 staff

There is no specific ERP system for surface treatment

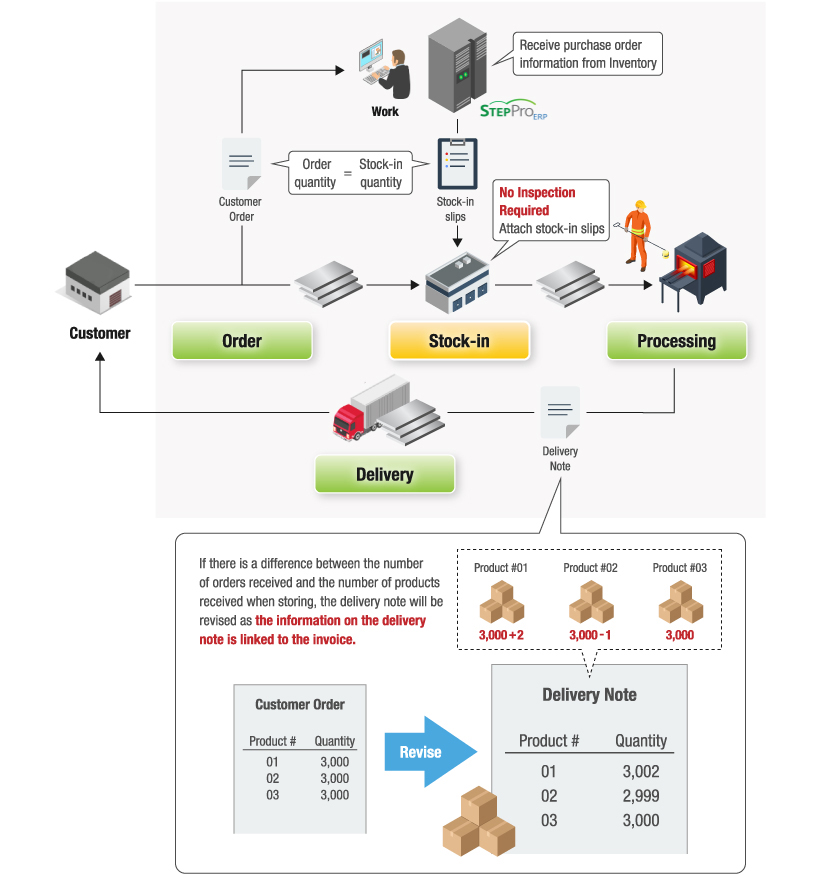

A general ERP system is unsuitable for stock-in processing flows in the surface treatment processing industry due to differences in the workflow, e.g. the stock-in quantity is the amount shown on the delivery note and not the actual quantity of items received.

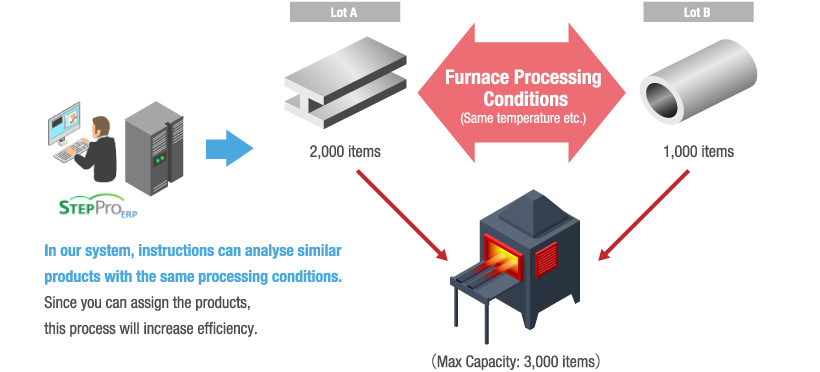

Due to a business model focused on a small quantity but wide variety of processed products, the furnace capacity is not being used efficiently.

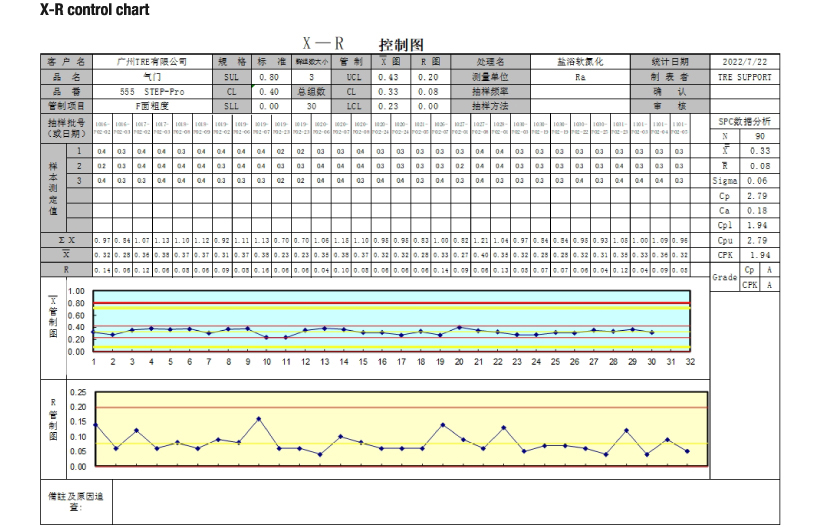

The creation of X-R control charts in Excel is time-consuming.

![]()

Improve efficiency with a system specialised for surface processing

Instead of counting the goods-in after inspection, the stock in/out operation will be tailored to fit the business flow when the system counts the goods-in quantity based on delivery notes.

(A characteristic of the surface treatment industry: number of orders = number of goods received)

By collecting different processed products from the same conditions in the same furnace, we aim to improve the operating rate of the furnace (assign processed products according to furnace conditions and capacity)

Enable the system to output X-R control charts. Furthermore, the inspection items for each product would be standardised, using master management to enable uniform quality control.

Time Rise Engineering Ltd.

Unit 15-18, 23/F., Standard Chartered Tower, Millennium City 1, 388 Kwun Tong Road, Kwun Tong, Kowloon, Hong Kong

+852-2781-4113

Guangzhou TRE Computer Technology Co., Ltd.

Unit 2004-2005, Southern Securities Building, 140-148 Tiyu East Road, Tianhe District, Guangzhou, Guangdong, China

+86-20-3887-8299

Shanghai Branch

Room 105, 9/F, WeWork (YueShang Building), No.1 South WuNing Road, JingAn District, Shanghai, China

+86-21-6427-0569